Process: Aluminum Die Casting + Shot Blast + Spray + Assembly

Product Name: Explosion proof electrical box

Main Use: Used in auto, machinery industry ,machinery industry

Technical Parameter

Technology: | Aluminum Die Casting + Shot Blast + Spray + Assembly |

Material: | Aluminum ADC12 A380 A263 A356 |

| Material Standard: | ASTM |

Weight of Raw Casting: | 0.53 - 2.6KGS |

Casting Dimension Tolerance | CT5-CT6 Grade |

Casting Surface Roughness> | Ra3.2-6.4 |

| Machining Surface Roughness | Ra0.8-1.6 |

Support Drawing File Format | ProE (.igs , .stp) , Auto CAD , PDF, Jpeg, Jpg, Png |

Product Process Documentation | Product Casting Process Card, Machining Process Card, Product Inspection Card |

Heat Treatment: | Solid Solution Treatment(1050 degree heat preservation 2H above) |

Precision Machining Equipment | 50 CNC Machines, 800 Vertical Machining Center |

Measuring Tool: | Three Coordinate, Micrometer, Caliper, Height Gauge |

Inspection: | Three Inspection: First inspection, Inspection, Final inspection |

| Available Report: | Casting CF8 or CF8M Material Report, Product Ddimension Inspection Report |

Technological Process

1.Casting Mould for Aluminum Explosion proof electrical box

2.Casting Shell of Aluminum Explosion proof electrical box

3.Casting Blank and Machining of Aluminum Explosion proof electrical box

Tianhui Factory

Tianhui CNC's Shop

Tianhui CNC Center's Shop

Quality Control

Magnetic particle testing

Production Processes & QC Reports

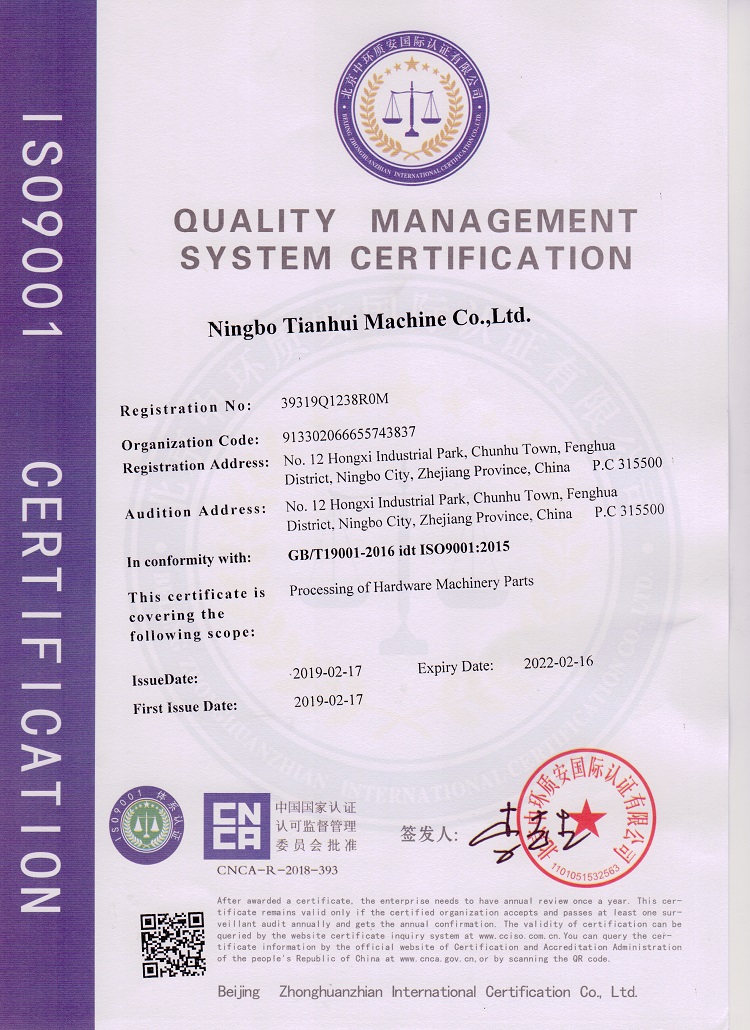

ISO9001:2008 Certificate of Quality Management System

Safty Packing

>

>